Print the future

The "ink" that the construction-based 3D printer uses includes a considerable proportion of waste materials from construction and industrial use as well as mine tailings, meaning savings on the total cost of at least 50% if you also consider the manpower saved.

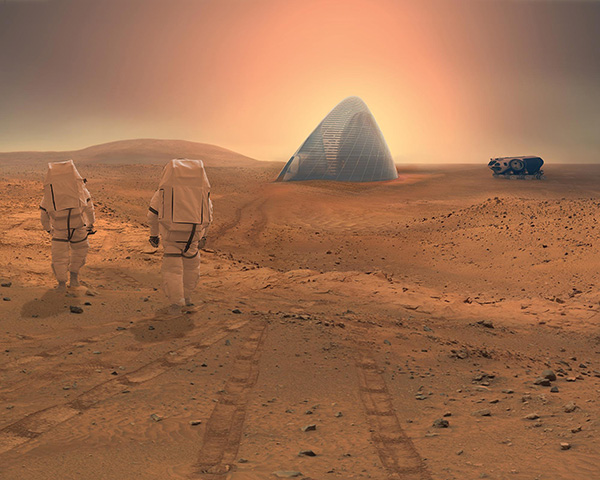

In the pursuit of another universal good, NASA and its partners launched the multi-phase 3D-Printed Habitat Challenge in 2015, welcoming public proposals on how to build an off-world 3D-printed habitat for deep-space exploration. The Phase 1 winner was the Ice House (pictured right) by New York-based Clouds Architecture Office, which could use water to create a multilayered shell of ice as a protective home for explorers under the harsh atmosphere of Mars. Phase 2 followed in August 2017, with a focus on creating the technology necessary to print a structurally sound habitat. The next phase of the challenge involves the creation of miniature habitats for astronauts using "indigenous materials" from the intended location, such as Mars or the moon.

When the future is printable, it seems there are limitless possibilities ahead and, as technology continues to be mastered, these pragmatic solutions can be highly beneficial for the human race.